With global environmental awareness at an all-time high, Juniper Networks is committed to ensuring networking is a force for good by taking important steps in sustainability, such as reducing carbon emissions and incorporating sustainability throughout our product lifecycles and product packaging.

Traditional packaging design and materials create environmental challenges, particularly when it comes to plastic waste. Over the last three or four years, Juniper has made significant advancements in product packaging across various areas. These include the transition of virgin PE foam to recycled PE foam, substitution of recyclable HDPE for PE foam, reduction of package volume, completion of other targeted modifications which is the reduction of pallet weight and use of straw-based material for corner boards.

As both company and customer interest in sustainability has grown, Juniper’s packaging team has established a set of sustainable packaging design principles:

- Make sustainability a priority, including the use of materials that are recyclable or biodegradable

- Use as few material types as possible for easier disposal and less environmental impact

- Design packaging for disassembly, since the end user will ultimately be responsible for cleaning and separating the packaging components for recycling and disposal

- Investigate and use bulk shipments where it makes sense, to reduce packaging waste

- Reduce plastics to a minimum

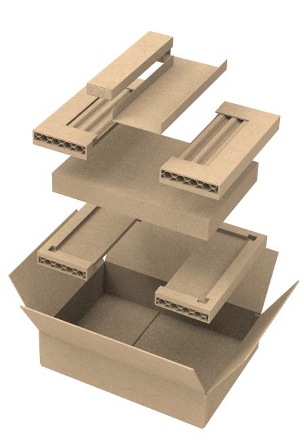

Recently, the team evaluated several innovative materials for use on new products after applying these guidelines and in collaboration with our primary packaging supplier, Nefab. As a result, the Juniper packaging team selected a new material, FiberFlute – a fiber-based packaging solution that provides outstanding cushioning performance for a wide range of applications. The material provides a significant reduction in plastics and landfill waste while maintaining optimal product protection. With the use of this fiber-based solution, plastics are not used in the key carton assembly components.

Benefits of FiberFlute

- 100% renewable material, 0% use of plastics

- Forest Stewardship Council (FSC) certified

- Fully recyclable (naturally decomposes)

- Recyclable in most locations

- Good cushioning properties

Figure 1: FiberFlute Packaging Solution at Juniper

Figure 1: FiberFlute Packaging Solution at Juniper

Further feasibility studies conducted for Juniper demonstrated that the FiberFlute solution may work well for products and shipments weighing less than 70 pounds. Our next steps will include an investigation of options for units over 70 pounds, as well as bulk packaging shippers for some cables. The Juniper packaging team is also interested in identifying an alternative sustainable Anti-Static Discharge (ASD) bag for product protection that eliminates more plastic.

The path toward sustainability presents challenges, such as possible cost and process issues, but conquering these hurdles is necessary to achieve our sustainability goals. The eco-friendly packaging that Juniper is adopting, designed by Nefab, has not only reduced environmental impact but has also furthered the sustainability goals of customers, such as Deutsche Telekom, as they aim for full circularity – which means zero waste. This is an important sidebar, as supporting our customers on their sustainability journeys is a key part of our own.

The journey is an ongoing process requiring continued investigation of new materials, design concepts and technologies. Juniper is committed to the elimination of plastic, the reduction of packaging volume and the use of single-type compostable materials on systems packaging for our products where practical. One of our goals is to use a compostable solution on the majority of our smaller form factor products by 2025.

To learn more about our sustainability efforts, visit our 2023 Corporate Social Responsibility report.