Each year the world generates 2.6 million tons more e-waste than the prior year—with the annual total expected to reach 82 million tons by 2030. Slow adoption of recycling means billions of dollars of critical raw materials are not in the value chain even as some of those materials become scarce.

As IT infrastructure continues to grow, so does demand for network hardware products and the underlying need for circuit boards and other electronic parts and components that rely on these scarce raw materials.

Juniper believes reused and regenerated assemblies, parts, and materials, along with robust recycling networks, are essential elements of the solution.

Circularity means more than recycle

To address these issues, our industry has made great strides toward what is called the “circular economy” or “circularity”. It’s more than just recycling, though that is a strong component. It’s attention to materials used in the product including recycled content, and understanding which applications of reused and refurbished parts and products are suitable.

Circular thinking is not new. Almost 10 years ago, Juniper started a certified pre-owned program (JCPO) to begin extending the life of our products. Over 90% of materials in a certified pre-owned product are from the previously existing product—without impacting performance. The JCPO program has seen growth and now includes more than 1,000 participating customers globally.

We continue to listen to the marketplace. Frequently customers tell us they want to see pre-owned products when presented with product options, so we questioned them further to assist in our circular program design. Research points to double-digit growth in the channeling of e-waste to recycling vendors over the next five years, suggesting more participants in the marketplace are moving toward a circular approach with decommissioned products.

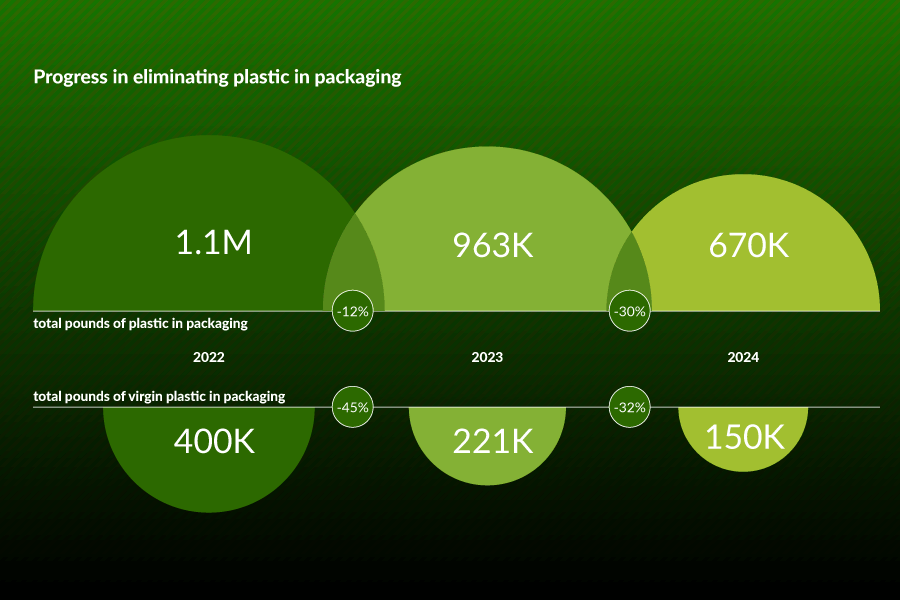

Packaging improvements

Among Juniper’s circularity priorities in 2024 is eliminating virgin plastics from our packaging materials and leveraging suitable substitutes. Our plastic packaging reductions will make it possible to reduce virgin and non-virgin plastic use by 40% by 2025. To reinforce the effort, we will ensure new products have packaging designs with less than 1% plastic as part of the total weight.

Take Back

Our current advancement in circular product management is twofold.

First, through our Take Back program, Juniper will take back any decommissioned Juniper product from customers, queuing it for refurbishment if possible or otherwise disposing of it through an R2-certified recycler, no matter its location. This offers our customers the opportunity to dispose of materials at no cost while having a transparent chain-of-custody and documented carbon emissions for the end-of-life process.

Secondly, we’ve developed a badging designation that will recognize and embolden our partner network by designating them as circularity collaborators for contributing to Juniper’s circular product motion. The effort aims to create an ecosystem of sustainability advocates.

Juniper’s commitment to sustainability embodies extended producer responsibility by holding ourselves accountable for the environmental impact of our products and driving innovation towards circularity. This approach puts system design for products and packaging at the forefront, compels the use of high-functioning recycling systems, and plays a vital role in reducing Scope 3 emissions of Juniper and our customers.

Juniper will continue to include our stakeholders in our sustainability efforts and seek their input. We hope all our sales partners will choose to be badged and participate in our circular programs. Please share your thoughts or interest in partnering with us on circularity here.

Rami Rahim, Juniper CEO, recently explained our Climate Commitment and reiterated that our emissions reduction journey includes our products. This same concern for the environment is reflected in our approach to circularity.

Learn more about our Sustainability initiatives in our latest Corporate Social Responsibility report.